Allpax has aftermarket solutions to help your operation minimize downtine and maximize production. Click here to view our offerings.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

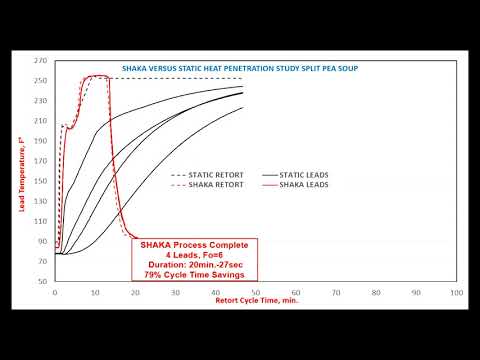

learn moreThe SHAKA™ process can deliver Chilled or Aseptic quality at shelf stable costs. Because SHAKA™ decreases process times, shelf stable products can be created with the quality of a frozen product. Unlike Aseptic equipment, SHAKA™ retorts can process products containing particulates while matching the same quality of an aseptic process.

Production SHAKA™ retorts feature Batch Flexibility along with Container Flexibility. A SHAKA™ retort can process many retort-able container types including trays, pouches, cans, and glass jars. With automated loading and clamping options, the SHAKA™ retort is a drop in replacement that adds value. And with a batch retorting system, changing product lines is as simple as re-loading the machine!

Because the SHAKA™ process features lower process time, increased product quality, and improved nutritional value new product lines are being created. Products that could not be retorted in the past can be processed in a SHAKA™ retort. Not only can sensitive products be retorted, but they can be processed with qualities superior to frozen foods. SHAKA™ retorts are changing the landscape of shelf stable products.