Retort Temperature Distribution and Container Heat Penetration Testing

The thermal process known as commercial sterilization consists of the application of a lethal amount of high heat to effectively kill spoilage and pathogenic organisms such as bacteria and molds. One of the most resilient of these organisms is Clostridium botulinum bacteria. The non-vegetative spore of this particular pathogen is very resistant to high heat. To ensure that commercial sterilization is accomplished effectively, there are two protocols that are performed by process authorities and thermal process technicians. Because of the dangers that exist if an under processed product is released into the food stream, these two tests are vital to the insurance that a shelf-stable, low-acid product is safe for human (and pet) consumption. Here we will have an in-depth look at these two testing methods and the types of hardware and software that provide process authorities, thermal process technicians and food scientists the ability to validate retorts, thermal processes and to develop formulations for shelf stable low-acid food products.

Retort Temperature Distribution

A temperature distribution (TD) test is an evaluation method used to determine the time it takes a retort to reach a prescribed temperature and how homogenously the heating medium (steam and/or water) is distributed throughout a retort loaded with product. Depending on the size of the retort, a number of thermocouples are placed within a ballast load which is typically water filled containers representing the densest load that will be processed in the retort. Placement of the probes is determined partly by the type of process and method of agitation if there is one. Regardless of where the temperature probes are placed, with TD testing, the more data points that are recorded, the better the accuracy in determining where the retort cold spot is.

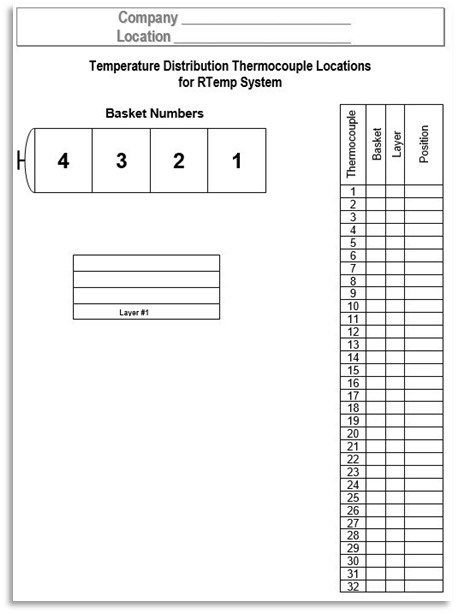

Example of a thermocouple location document for a retort temperature distribution test

All thermocouple locations are mapped out in a visual representation of the retort load, i.e. which layer in the basket or tray in the stack as well as the location in that layer or tray. The retort cold spot is the location or locations of the retort load that take the longest time to come up to the programmed sterilization temperature. Armed with the location of the cold spot and the time it takes for that cold spot to come up to sterilization temperature, the retort and the retort process can now be validated for that application. Any changes that alter any critical factor of that process such as installing a boiler with a different operating pressure, a pump or a valve with a different flow rate, or using retort baskets, divider sheets or trays with differing amounts of open area, a new TD validation test must be performed.

Container Heat Penetration

A heat penetration (HP) test is performed on a specific food product and retortable container combination to determine the time and temperature required for the product/container combination to reach a desired degree of lethality. As with TD, the cold spot within the container must also be determined. Considerations when performing HP testing include all product and container attributes that can affect the heat penetration within a hermetically sealed container of product. This penetration of heat throughout the container has two forms – conduction and convection. Conduction is how heat penetrates the product from the outside towards the geometric center or highest horizontal and vertical cross section of the container. Convection occurs when liquid flows up along the container wall and then back down the central vertical axis of the container. Below is a partial list of product attributes that can affect heat penetration into a product:

- Viscosity

- Setting of starches and gums

- Fat content

- Absorption of liquids by solids

- Ratio of solids to liquids

- Headspace

With static retort processing, conduction heating occurs in high viscosity/consistency products such as refried beans, canned ham and some vegetable & fruit purees, while convection heating occurs in low viscosity/consistency products such as broths and ready-to-drink beverages. Three types of instruments used to measure the viscosity and/or consistency are rheometers, viscometers and consistometers.

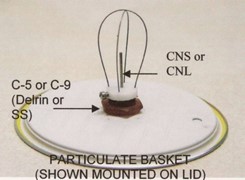

Particulate basket attached to a needle-type thermocouple. Image courtesy of TechniCAL

Additionally, a combination of the two heating methods will occur in products with particulates and liquid components such as vegetables in a brine solution. In such products the particulate, in which conduction heating occurs, the largest foreseeable particulate must be impaled onto the temperature probe that is positioned in the container cold spot. The use of retort agitation methods such as end-over-end & axial rotation or horizontal reciprocation such as Gentle Motion and SHAKA™ will impart forced convection into a product. Agitation also allows for a more homogeneous distribution of heat within the container. With forced convection, which is basically stirring the product in its sealed container, products that would otherwise be undesirably affected by high heat can be successfully commercially sterilized. Considerations need to be made when agitation is used with impaled particulates to ensure the particulate remains impaled.

Hardware

The temperature probes used in the thermal process evaluations are quite varied as the myriad of retorts, retortable containers and food products have their own specific requirements. While there are numerous types of thermocouples (TCs), the type-T is most used because of its inherent accuracy in the temperature range of commercial sterilization (≈250°F/121°C). Wired and wireless TCs, each with their own benefits, are used in HP and TD testing. Wired and wireless transmitting TCs afford real time temperature data acquisition in process development. Wireless dataloggers allow data acquisition in continuous thermal processes such as continuous hydrostatic and rotary pressure sterilizers. Different types of retortable containers will need their own type of probing method.

Above are some examples of how various container types are probed for HP testing

Because of the potentially lethal dangers that exist with under-processed foods and beverages, the United States Food and Drug Administration and Department of Agriculture regulations, as well as those of other reputable food regulatory agencies in other countries, every retort that processes a shelf stable low-acid food or nutraceutical product has had a temperature distribution evaluation. Additionally, every low acid product that anyone has consumed has undergone heat penetration testing. In summary, retort validation through temperature distribution studies and in-container heat penetration testing during product development are two vital tools that human and pet food, beverage and nutraceutical manufacturers use to keep low-acid foods and beverages safe for consumers. Properly stored, these products do not require the need for refrigeration and will have a shelf life of months, if not multiple years.